I. Foundation Engineering Preparation

Site treatment: Remove debris and compact the soil, with a compaction coefficient of ≥95%. The slope should be controlled at 3-5‰ to facilitate drainage. If it is a concrete foundation, C20 strength concrete (with a thickness of 20cm) should be poured, and expansion joints should be set every 5 meters and filled with asphalt hemp.

Drainage system: Check the patency of the drainage pipes. The middle of the base layer should be slightly higher than the periphery to ensure the rapid drainage of rainwater.

Ii. Key Steps for Lawn Laying

Material acceptance: Check the density of the turf (it is recommended to be 9450 needles per square meter), height (50mm for filling type) and environmental protection performance.

Precise layout: Mark the site point lines according to the drawing, with an error of no more than 3mm. Pre-cut green turf in the white line area.

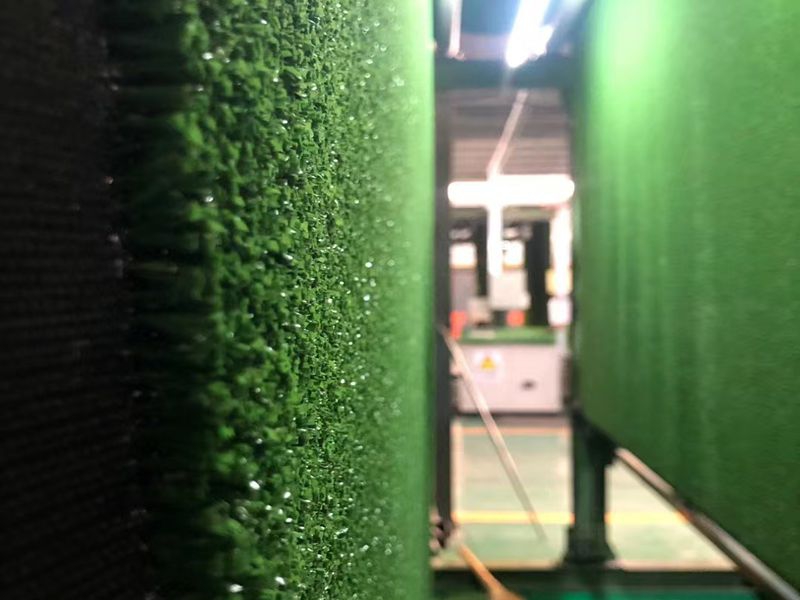

Splicing process:

Use a 20cm wide joint tape, apply special glue and overlap it by 10cm for bonding.

Let the glue stand for 15 to 30 minutes (at a temperature above 5℃) and then press it firmly with a hammer.

Iii. Filling and Curing

Layered filling

The dosage of quartz sand (0.2-0.8mm) is 20kg/㎡, and it should be evenly spread in different areas.

The dosage of rubber particles (0.5-2mm) is 3.5kg/㎡. After covering, brush it flat.

Curing maintenance: After bonding, maintain for 3 days. Avoid direct sunlight or heavy pressure within 10 days.

Iv. Acceptance Criteria

Flatness: The measurement error of a 2-meter straightedge is ≤±3mm.

Joint gap: ≤5mm and no lifted edge