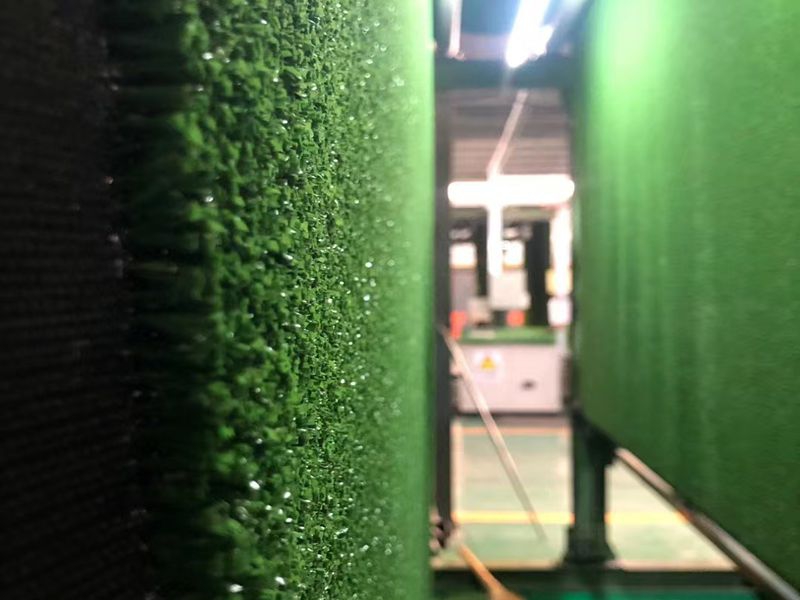

The artificial turf for football fields is a special sports ground material made of non-toxic polymer materials, featuring anti-slip, wear-resistant properties and excellent elasticity. By 2025, mainstream products will adopt a 50mm grass height specification, with a service life of 5 to 8 years, and be filled with 20-40 mesh quartz sand particles to enhance sports performance. The product is compatible with cement or asphalt concrete foundations. Some high-end products are equipped with XPE buffer and shock-absorbing cushion layer structures

Material properties

It is made of high-density polyethylene (HDPE) or polypropylene (PP) as the base material and forms a structure imitating natural grass fibers through the drawing and tufting process. The surface is added with ultraviolet stabilizer to ensure color stability and anti-aging ability in outdoor environments, meeting the national standard for anti-slip coefficient of artificial turf in football fields. It is filled with 20-40 mesh quartz sand particles

Structural parameters

Grass filament density: The standard product has 10,500 to 16,800 tufting needles per square meter

Filling layer: A mixture of rubber particles at the bottom layer and 20-40 mesh quartz sand at the top layer is used for filling. The recommended laying thickness is 20-30mm

Shock absorption system: XPE shock-absorbing pads can absorb impact forces and reduce the risk of joint injuries for athletes.

Construction foundation

Construction must be carried out on a cement or asphalt concrete foundation with a flatness error not exceeding 3mm, and the joints should be bonded with special glue. The standard construction plan for a five-a-side football field includes: foundation treatment → layout and positioning → turf laying → joint bonding → filling with quartz sand → field marking