Our products are produced purely from raw materials and do not contain any recycled materials. German BASF stabilizer with excellent weather resistance and ultraviolet (uv) resistance. Through anti-aging technology, the fiber life of artificial turf can be increased by 30%-50%, and it still maintains elasticity and color under long-term sun and rain, reducing the replacement frequency and cost.

- High temperature and extreme climate tolerance

Basf’s antioxidants, such as the Irganox® series, inhibit thermal oxidation reactions and prevent hardening or cracking of materials at high temperatures, making them suitable for harsh climates such as tropics and deserts.

- Environmental protection and safety

The products comply with international environmental standards such as REACH, do not contain harmful substances such as heavy metals, and are suitable for scenes with high safety requirements such as children’s activity areas and sports venues.

- Color persistence

Anti-aging additives reduce the breakdown of pigments, maintain the green appearance of the lawn for a long time, and avoid yellowing or fading caused by ultraviolet light.

- High strength bonding and durability

Excellent adhesion: Dow styrene butadiene latex can firmly bond artificial grass silk with the base cloth (such as PP/PE fiber and mesh cloth), reduce the loss of grass silk, extend the service life of the lawn.

Resistance to repeated impact: the cured adhesive layer is flexible and wear-resistant, and can withstand long-term trampling and instrument friction (such as high-frequency use in sports venues) to avoid cracking or pulverization of the back adhesive.

- Environmental protection and low VOC emissions

Solvent-free formula: Dow styrene butadiene latex with water as a dispersing medium, almost no volatile organic compounds (VOC) release during production and use, in line with EU REACH, US LEED and other environmental standards.

Recyclable compatibility: Compatible with common artificial turf materials, supporting the recycling of waste lawns and reducing the environmental burden.

- Fast curing and production efficiency

Low temperature film formation: latex can quickly form film at room temperature or low temperature, reducing baking energy consumption and improving production line efficiency.

Low foaming: It is not easy to produce bubbles during the coating process, to ensure that the back glue is uniform and smooth, and to reduce the defective rate.

- Weather resistance and stability

Aging resistance to humidity and heat: in high humidity and high temperature environments (such as rainy areas or around indoor heated swimming pools), the rubber layer is not easy to hydrolyze or mold.

Wide temperature range adaptability: Elastic in the range of -30°C to 70°C to avoid winter cracking or summer softening deformation.

- Economy and cost performance

Small amount, strong coverage: high solid content formula (usually more than 60%) can reduce the amount of flat rice glue and reduce the comprehensive cost.

Low maintenance costs: Stable bonding performance reduces the need for repair during use, suitable for budget sensitive projects (such as community courts, school playgrounds).

- Safety and applicability

Non-toxic and harmless: no irritating odor after curing, through SGS and other safety certification, suitable for children’s activity areas, kindergartens and other sensitive places.

Compatible with a variety of substrates: suitable for different material substrates (such as polypropylene, polyester) and fillers (such as quartz sand, rubber particles), flexible application scenarios.

Practical application case

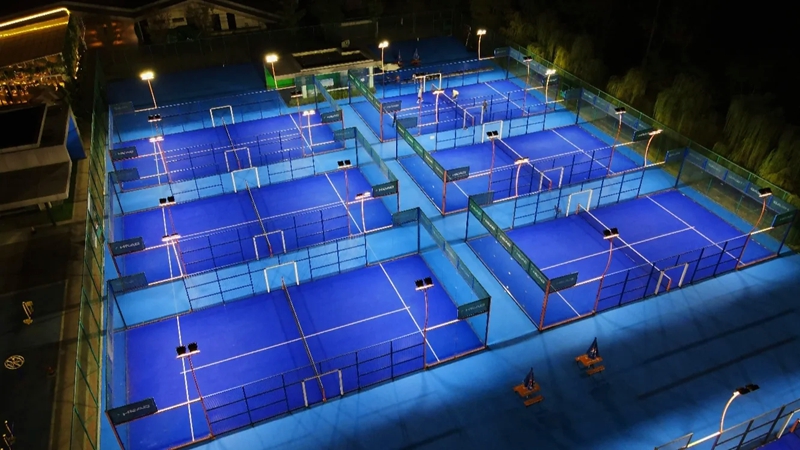

Playing field: The FIFA-certified multi-artificial turf field uses Dow’s rubber back system to ensure that the grass silk remains stable during intense sports.

Landscape Engineering: Urban roof greening projects take advantage of their weatherability to cope with extreme temperature differences and rain erosion.