The construction of artificial turf mainly includes six core steps: site preparation, measurement and layout, turf laying, joint treatment, filling materials and acceptance and maintenance. It is necessary to strictly follow the process standards to ensure quality.

Youdaoplaceholder0 Site preparation and foundation treatment

Youdaoplaceholder0 1, cleaning and inspection : Remove debris, stones and other obstacles from the site to ensure the foundation is level (the measurement error of a 3-meter straight ruler is ≤3mm), and the concrete or asphalt base layer must reach the designed strength (such as C25 concrete).

2, drainage system : Check the slope (0.3% to 0.7%) and the pre-buried drainage pipes to ensure there is no water accumulation after rain.

Youdaoplaceholder0 measurement and layout

Use a total station or theodolite to locate the center point of the field and functional lines (such as the sidelines of a football field or the penalty area lines), with an error controlled within 1cm.

Mark out the laying direction of the non-woven fabric (at a 90° Angle to the artificial turf) and the position of the turf splicing according to the design drawings.

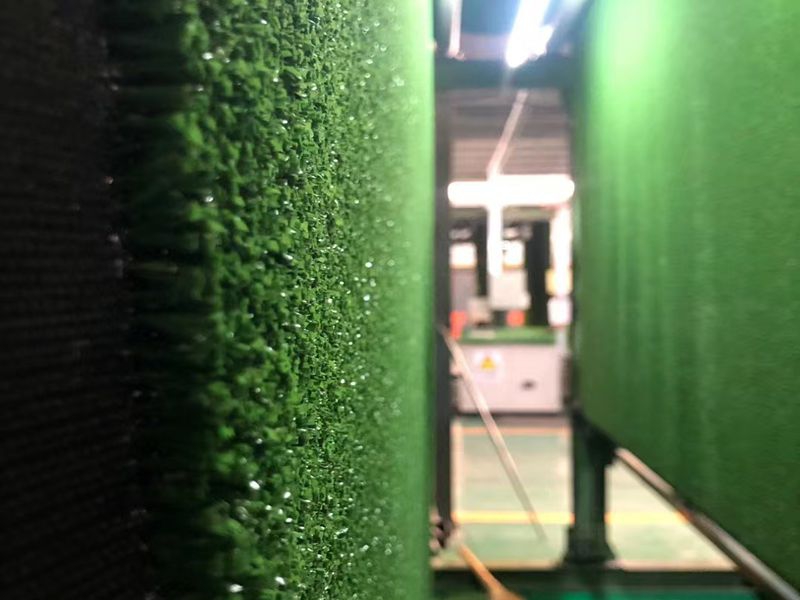

Youdaoplaceholder0 Lawn laying and splicing

Youdaoplaceholder0 Laying the lawn : The grass rolls need to be left to rest and relieve stress before being unfolded along the marking direction. The direction of the grass fibers should be consistent to avoid color differences.

Youdaoplaceholder0 seam treatment :

Overlap adjacent lawns by 2-3cm, cut them evenly with a cutter, and lay 20-30cm of seam fabric at the bottom.

Apply the special glue (with a width of ≥5cm). When the glue surface is 80% to 90% dry, bond it together and press it firmly with a rubber mallet.

Youdaoplaceholder0 functional line construction : Cut the white grass line area, embed the joint tape and bond it, with a width error of no more than 2mm.